Recently, Depu CNC, which focuses on the research and development, production, and sales of high-end five axis CNC machine tools and their key components, completed a Series A financing of tens of millions of yuan, and Zijingang Capital once again led the investment in this round of financing. Depp CNC's Pre-A round of over 10 million yuan financing at the beginning of this year was also led by Zijingang Capital.

At present, Depu CNC has received investment from well-known institutions such as Share Investment and China Incubation Capital, and has been highly recognized by the capital market.

In 2024, Depu CNC continued to focus on research and development, successively launching upgraded models of the G series and V series, and successfully developing and mass producing the U series large vertical and horizontal five axis machine tool. Based on its high-quality products, first-class service level, and reliable delivery capabilities, the new products have received widespread attention and unanimous recognition from new and old customers since their launch, and the total order volume has doubled year after year. The funds raised in this round of financing will mainly be used for research and development investment, operational management, team building, etc.

Depu CNC was established in 2021 with strong R&D capabilities. The core team of the company has been deeply involved in machine tool research and manufacturing for many years, focusing on high-end machine tool R&D and manufacturing for a long time. It has a good reputation in the sales of five axis machine tools. The brand awareness and market reputation of the group are rapidly improving, and high-end five axis linkage machine tools have been put into mass production, with sales networks covering the Yangtze River Delta, Pearl River Delta, and overseas fields.

Depp CNC has a strong R&D strength. The team has been deeply involved in the field of machine tool R&D and manufacturing for many years, focusing on the R&D and manufacturing of high-end machine tools and accessories for a long time, and has established a joint research center with the State Key Laboratory of Mechanical Transmission of Chongqing University to carry out in-depth research in core transmission devices, machine tool design and manufacturing and other fields. At present, both parties have applied for multiple invention patents and mastered multiple core technologies. We have rich experience in product development in five axis machine tools and their core components (four axis, five axis CNC turntables, swing heads, etc.). Our products currently have a leading market share in the industry, with a good reputation and have been recognized by high-quality customers such as BYD and Foxconn. We have accumulated a large amount of product data and provided good support for product iteration.

Depu Group has been working in the equipment manufacturing industry for many years, with world-renowned processing and testing equipment. With standards higher than international and domestic standards and customer requirements, we have established an internal quality assurance system, implemented comprehensive and full process quality management, and strictly monitored the quality of each link in production and processing, striving for excellence. The Group has always adhered to scientific design concepts and methods, jointly developed with the State Key Laboratory of Mechanical Transmission of Chongqing University, constantly challenged product innovation and performance improvement, pursued excellence, and worked hard to provide better products for the market and boost industrial development.

Precise positioning and commercial layout of Depu CNC

Location! To produce cost-effective products among high-end CNC machine tools worldwide

Depp CNC defines its industry strategy as: high cost-effectiveness in high-end products+high-quality service.

Currently, Depu CNC has polished the product performance to world-class level and successfully developed and mass-produced G series - G600 \ G800, V series - V866U \ V1160U, U series products.

G800

Among them, the G series is a high-performance and high-efficiency 5-axis machining center, mainly aimed at the production of precision molds and high-precision parts in the fields of automotive, mechanical engineering, aerospace, etc. Adopting a gantry type machine tool structure, equipped with high rigidity and high precision feed axis and spindle, double end support cradle turntable, standard configuration with a maximum speed of 20000rpm and a maximum torque of 89.5N. m electric spindle. The G600 has achieved a comprehensive improvement in overall performance based on the G500 product, and can process the tip parts of tilted workpieces that are further away. At present, the company has successfully exported G-series products to the German market, and G600 products have also been recognized by overseas customers, with orders continuing to expand.

V866U

V866U is a small, high-precision, and high rigidity five axis machine tool mainly used for small component processing in the 3C, automotive, and aerospace fields. After one clamping, the workpiece can automatically and continuously complete various processes such as milling, cobalt, boring, expanding, reaming, countersunking, and tapping. It has good dynamic responsiveness and can achieve high-speed cutting without crawling at low speeds, further manufacturing high-precision and high smoothness workpieces for customers. The development of V1160 mainly increases the cutting rigidity of the machine tool, which can process larger sized and heavier components, while improving the overall machining accuracy. At present, V866U has received official orders from domestic customers and has been verified on the customer side, successfully replacing imported machine tools from abroad. The V1160 product has also been mass-produced and sold.

U series

The Depu U series machine tool is a high-precision, high load bearing, and high-efficiency vertical and horizontal swing head five axis machining center product. After one clamping of the workpiece, the machine tool can complete rough and fine machining of drilling, expanding, reaming, tapping, milling, boring, and contour surfaces, and complete machining of five surfaces in one clamping. It is suitable for processing difficult to process materials such as aluminum alloy, titanium alloy and alloy steel, and is widely used for processing parts in aerospace, military, shipbuilding, automobile, water power, wind turbine, machine tools, molds and other industries.

It is worth mentioning that in the production and research and development process of the U series, Depu CNC has introduced Taiwanese experts to improve its internal process management level and further enhance its mass production capacity. This product has already achieved mass production capability.

The U series products have gained widespread attention from customers both domestically and internationally since their launch in 2024, quickly receiving tens of millions of large orders.

Layout! Build your own core component advantages

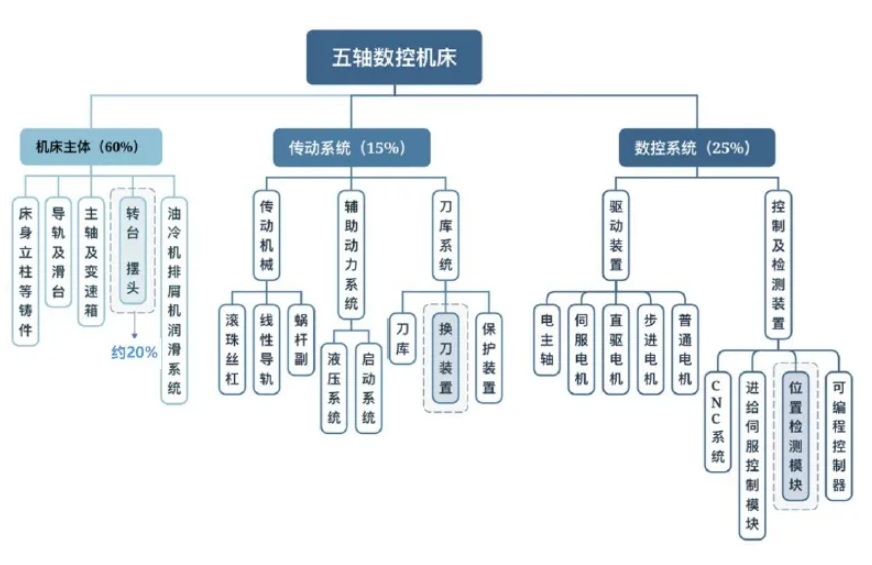

Depu CNC prioritizes the layout of turntables and pendulums, which account for a large proportion of the overall cost structure of the machine tool and determine the overall accuracy level of the machine tool. This increases the cost reduction space for the research and development of five axis CNC machine tools, and is expected to save about 20% of machine tool development costs.

The company has established a joint research center with the State Key Laboratory of Mechanical Transmission of Chongqing University to jointly research and develop the turntable and swing head of roller cam structure. At present, its roller cam turntable and single arm swing head have both been mass-produced and sold to domestic and foreign markets, and the product accuracy and performance can meet market demand.

The top 10 international giants in the industry all adopt an open research and development system, utilize advanced industry experience, and develop their own technological advantages based on their own characteristics. Depu CNC self-developed key precision component: time grating encoder - a measuring device that can replace grating technology and determine the machining accuracy of machine tools. The continuous optimization and cooperation with Southern University of Science and Technology on the time grating encoder algorithm is currently in the testing and optimization stage, and has applied for European patent protection. After the testing is completed, it can be put into the market and meet the actual needs of the market.

In addition, Depu CNC has also independently developed a tool changing device and a CNC system for secondary development, with an overall localization rate of 70%.

Zijingang Capital believes that five axis CNC machine tools are the key to advanced manufacturing, and there is huge room for localization substitution. Benefiting from the development of downstream high-end manufacturing industries and the overall trend of global manufacturing upgrading, there are significant market opportunities both domestically and internationally in the future. Depp CNC will become a dark horse in the industry by gathering high-end technical talents at home and abroad, introducing advanced production experience from Taiwan, China, China, mastering core technology, and building an internationally leading high-end CNC machine tool.

Hotline

+86 191 2931 4807

+86 191 2931 4807 103, Building l, Huahan Science and Technology Industrial Park,

No.19 Qiyun West Road, Heping Community, Pingshan Street, PingshanDistrict,Shenzhen,China